Squawks

No airplane is perfect, not even this one.

Squawk: The cabin can become drafty in certain situations.

Background: Air entering the cabin through the wing root behind the co-pilot becomes noticeable when flying at higher speeds, especially in cold weather.

Comment: Seal areas open to the wing root with neoprene foam rubber (or equivalent). See also Ted Setzer's innovative solution to stopping water leaks and reducing noise in the cabin, using weather stripping and Silpruf, infra.

Squawk: Main-gear tires wear unevenly.

Background: This squawk applies to GlaStars equipped with the original gear legs, including aircraft with tricycle or conventional landing gear.

Comment: The problem lies in how the gear legs were originally designed to fit into the GlaStar's cage sockets. The following are suggestions to extend tire life:

* Periodically remove and reverse direction of rotation for each main gear tire. Simply swapping wheels to the opposite side of the aircraft does nothing to distribute wear; each tire must be removed from its hub, flipped, and reinstalled onto the same hub.

* Where prop damage from weeds and gravel is not a problem, taxi, take-off, and land on grass.

* On taildraggers, replace landing gear with heavy-duty extended landing gear made by Langair Machining in Warren, Oregon. For details, see References.

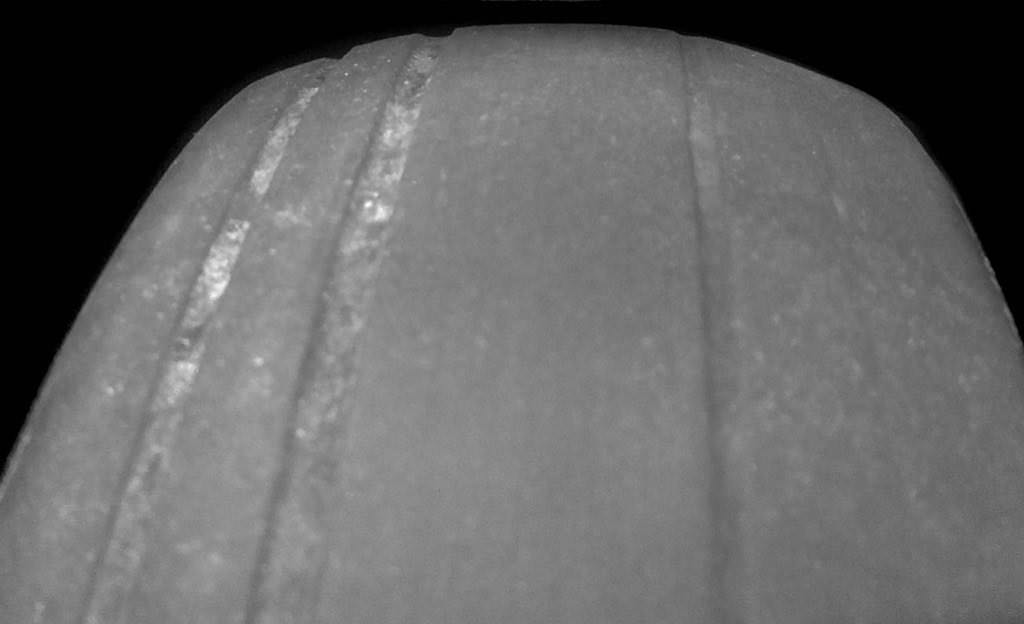

main-gear tire wear on my first GlaStar (tricycle)

Squawk: Gaps between the wings and fuselage sometimes allows water into cabin.

Background: In flight, the 2mm gap between the wings and fuselage may leak water into the cabin and baggage area, especially during periods of moderate rain.

Comment: 1. With wings folded, apply 3/16 in x 3/8 in foam weather stripping around wing roots, then return wings to normal (unfolded) position. 2. Apply blue masking tape to sides of edges of gaps, then apply GE Silpruf. (With a better sealed cabin, beware of CO.) For details, see Ted Setzer's solution to water leaks and noise in References.

in moderate rain, water can leak into cabin

Squawk: Short life of Dynon's EGT probes

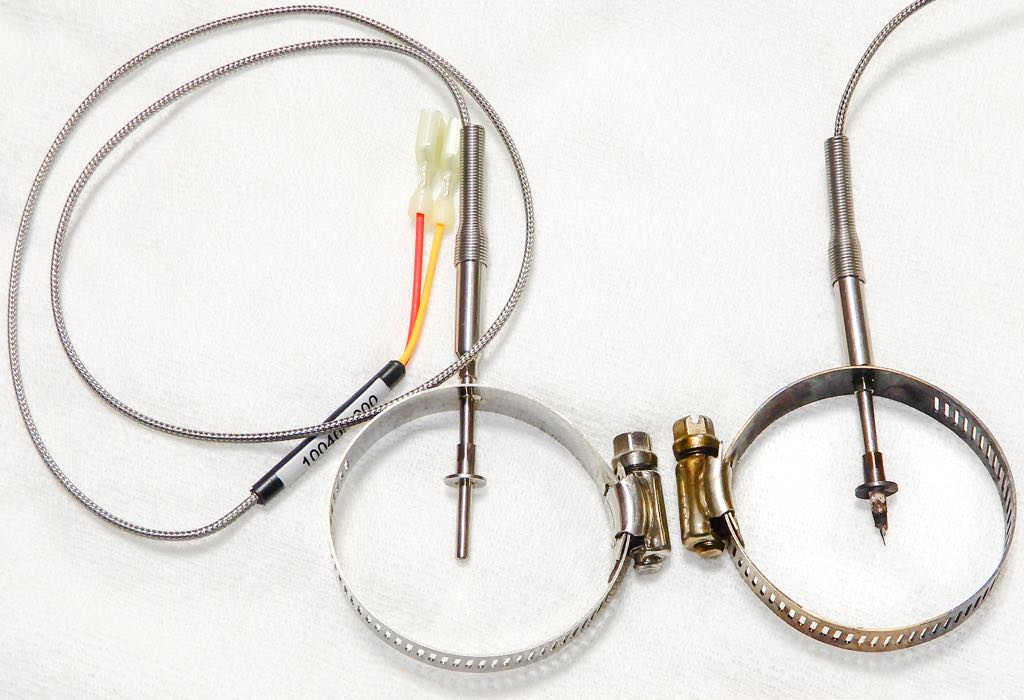

Background: Of the four Dynon EGT sensors installed in the engine of this aircraft, #3 failed at 191 hrs and #4 at 302 hrs since new. The part is Dynon's K-type EGT Sensor #100405-000 REV L (Aircraft Spruce part #: 10-01169, $36).

Comment: I run EGT temperatures about 1350° F, nowhere near peak EGT temperatures (+/- 1600°F). Furthermore, all EGT probes were equally placed at four inches below the exhaust-pipe flange.

According to Dynon Tech Support, "EGTs exist in harsh environments, with lots of heat and vibration. So one way they fail is the failure of the the actual probe that's in the exhaust. This can be hard to predict: some engines have consume probes regularly; others practically never" (Jones, 2015).

erratic readings prior to complete failure of Dynon's EGT sensor

comparison of new and old EGT sensors

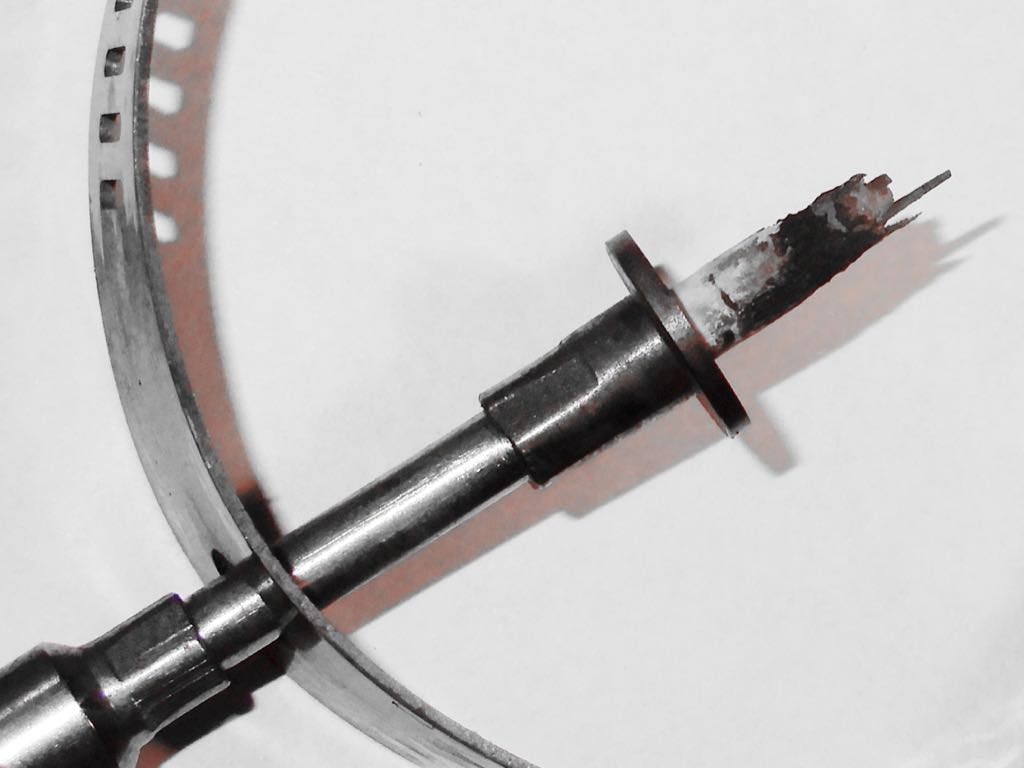

almost nothing left of EGT sensor probe

Squawk: When the weather approaches freezing, Maple's engine struggles to reach recommended minimum operating temperatures.

Background: The way to maintain oil temperatures within the engine’s recommended oil temperature range (190° F - 210° F at below 10° F ambient) is by controlling air flow into the oil cooler.

Comment: TWC Technologies produces a control-valve servo kit (not currently installed in Maple) that can be used to control engine oil temperature. The controller provides proportional operation of a linear actuator servo, allowing the motion of a butterfly valve to be adjusted to any position from fully opened to fully closed by means of a panel-mounted switch. The servo controls the flow of cooling air through the oil cooler, and thus also controls oil temperature. See References for details.

Squawk: Maple lacks run-away trim control.

Background: While this item is more a future project than a squawk, nevertheless, a dedicated trim servo speed-control system is a value-added safety feature missing in this aircraft.

Comment: TWC Technologies produces a two-axis Safety-Trim electronic servo speed-control system (not currently installed) that limits servo travel to 3 seconds per trim switch actuation, and allows the pilot to quickly recover from a stuck or failed trim switch. See References for details.

Squawk: Maple lacks toe-brakes on the right (co-pilot) side.

Background: The builder of the aircraft, Denny Lawrence, chose not to install toe-brakes in the interest of keeping the empty weight as low as possible.

Comment: Over time I gathered and prepared all parts and materials needed to install right-side toe brakes, but have been unable to find assistance to complete the project.

right side lacks toe brakes

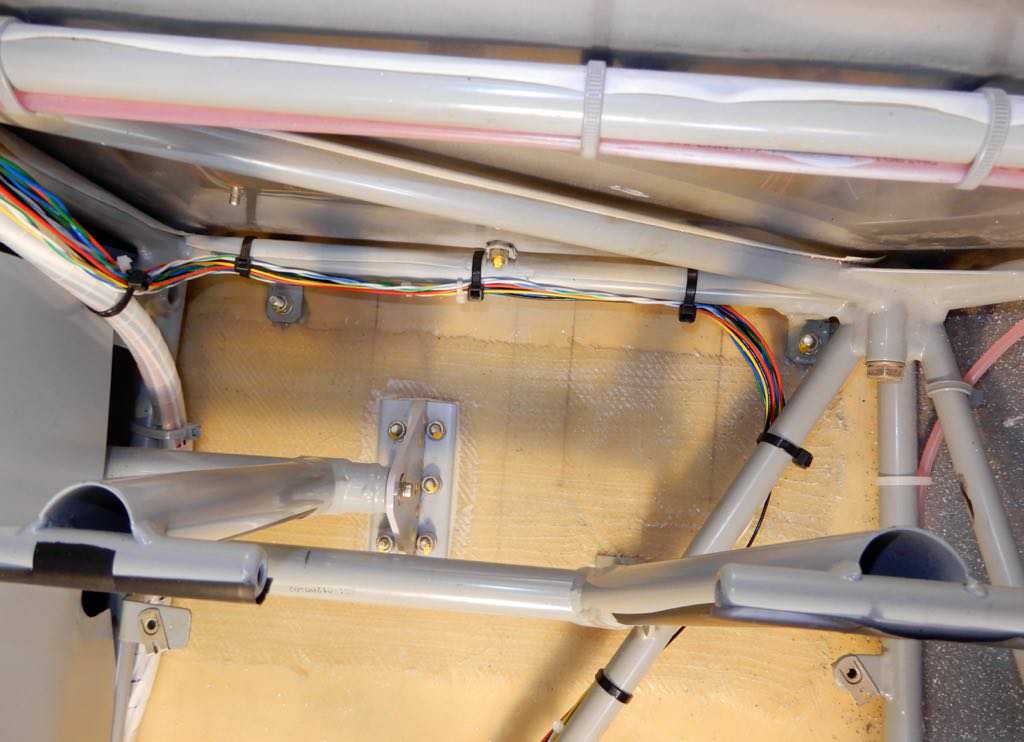

Information below provides the scope of work required to install right-side toe-brakes in Maple.

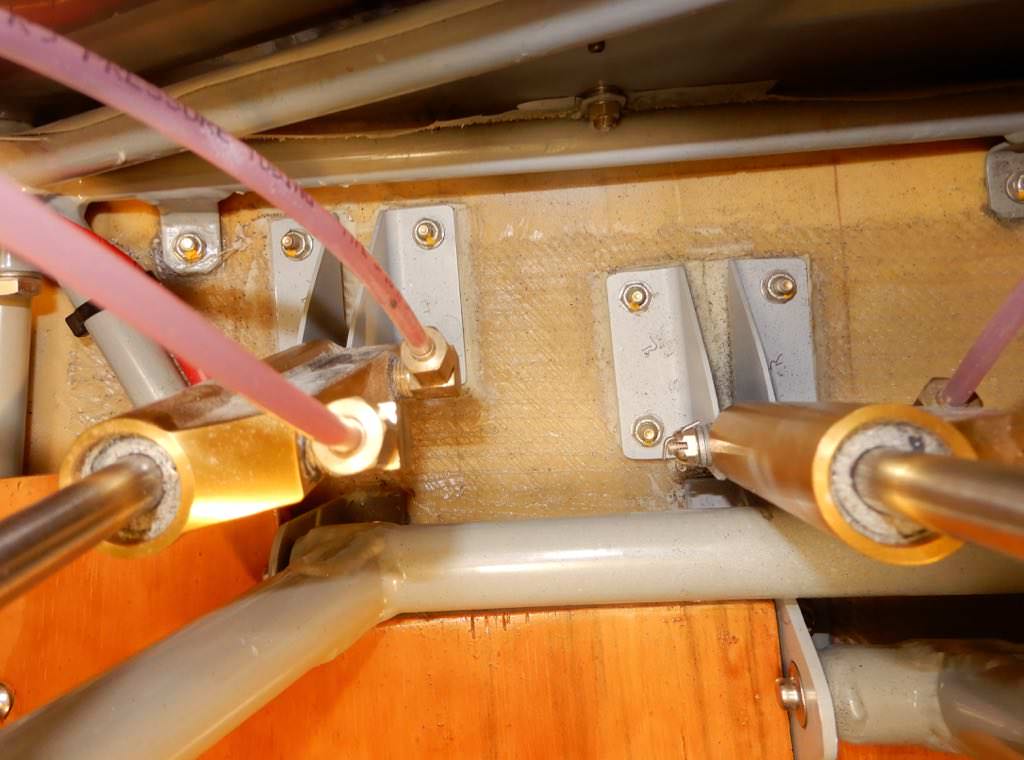

co-pilot-side rudder pedals

co-pilot-side rudder pedals

pilot-side rudder pedals

pilot-side brake master cylinders

pilot-side rudder pedals

pilot-side rudder pedal

pilot-side rudder pedal

pilot-side rudder pedal

pilot-side rudder pedal

pilot-side rudder pedal